100% ORIGINAL AND QUALITY

- Description

- Reviews

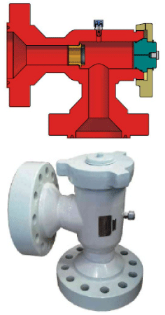

External Sleeve Cage Chock Valve

Standard Chock valves are in accordance with API 6A 21th latest Edition, and use the right materials for H2S service according to NACE MR0175 standard. Product Specification Level: PSL1 ~4 Material Class: AA~FF Performance Requirement: PR1-PR2 Temperature Class: LU

Chock valves include Positive Chock Valve, Adjustable Chock Valve, Needle Chock Valve, External Sleeve Cage Chock Valve, these valves are offered by CEPAI to different countries, and all designs as per API6A Spec strictly, moreover, we can design and make the special chock valves based on different requirements. Their seats and valve needle made by hard alloy, which improves the corrosion resistance, flushing resistance performance, and material of throttle nozzle made of ceramics or hard alloy, the torque of Cage type choke valve is small torque, it can both adjust and cut off the fluid etc, controlling the flow rate by replacing the throttle nozzle of different sizes.

Design Specification:

Standard Chock valves are in accordance with API 6A 21th latest Edition, and use the right materials for H2S service according to NACE MR0175 standard.

Product Specification Level: PSL1 ~4 Material Class: AA~FF Performance Requirement: PR1-PR2 Temperature Class: LU

Product Features:

◆ Small impaction and noise of fluid

◆ Body/bonnet materials include carbon steel, alloy steel, stainless steel and duplex stainless steel

◆ In-line or angle body options

◆ Valves can be automated with electric or pneumatic actuators

◆ Metal to metal shut off in accordance with ANSI class VI & V

| Name | Chock Valve |

| Model | Positive Chock Valve/Adjustable Chock Valve/Needle Chock Valve/External Sleeve Cage Chock Valve |

| Pressure | 2000PSI~15000PSI |

| Diameter | 2-1/16”~7-1/16”(46mm~230mm) |

| Working Temperature | -46℃~121℃(LU Grade) |

| Material Level | AA、BB、CC、DD、EE、FF、HH |

| Specification Level | PSL1~4 |

| Performance Level | PR1~2 |

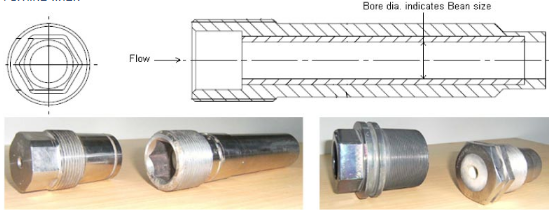

Positive Chock

• Field conversion kits from positive to adjustable choke and vice a versa.

• Bonnet nut with vent hole for safety during servicing.

• Body/bonnet materials include, carbon steel, alloy steel, stainless steel and duplex stainless steel to suit different applications.

Bean size

Increment between bean size diameters of 0.4 mm (1/64 in) to 50.8 mm (128/64 in).

Different material of construction of Beans

• Stainless steel • Stellite lined • Ceramic lined • Tungsten carbide lined

Basic construction of beans for Fixed Bean Choke

Gas Lift choke

Gas lift flow control valves are being made both in-line and angle body configuration with flange, threaded or weld end connections.

With a range of trim sizes and materials, these valves use a profiled plug moving into a seat to vary precise flow range thereby providing fine flow control.

JVS control valves have become the valve of choice in many gas lift installations.

Plug & Cage Chock Valve

The plug and cage trim uses a solid plug with a pressure balancing holes moving inside a ported cage to control flow. This design provides the maximum flow capacity for a cage trim choke valve. In closed position, the plug moves down closing the ports in the flow cage and makes contact with the seat ring to provide a positive shut off. Flow is directed into the trim via ports and impinges in the center of the flow cage.

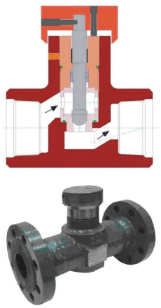

External Sleeve Chock Valve

The external sleeve type trim uses a flow sleeve moving over the outside of a ported cage to control flow. A metal to metal (optionally tungsten carbide) seat design on the outside of the flow sleeve and out of the high velocity flow assures positive shut off and an extended seat life. The controlling element (flow sleeve) moves in a lower velocity regime and leads to the high erosion resistance of this trim design. Applications of these chokes include high-pressure drops and fluids with entrained solids such as formation sands. This trim is normally supplied in tungsten carbide